International Conference on Computational and Experimental Engineering and Sciences (ICCES)

The International Conference on Computational and Experimental Engineering and Sciences (ICCES) is an organization of highly reputed international researchers, from academia, industry, and governments across the world, in the general disciplines of computational and experimental engineering and sciences.

We were invited to speak at the 2015 ICCES Conference in a special Symposium on Shape, Deformation and Strain Analysis, in honor of Professor James W. Dally. It was a thoroughly fascinating conference and opportunity to interact with remarkable people doing REMARKABLE things in computational and applied mechanics. You may consider attending this years event in Madeira, Portugal, during September 5 – 9, 2016, see below for a link. Thank you to Shien RI for the photograph below.

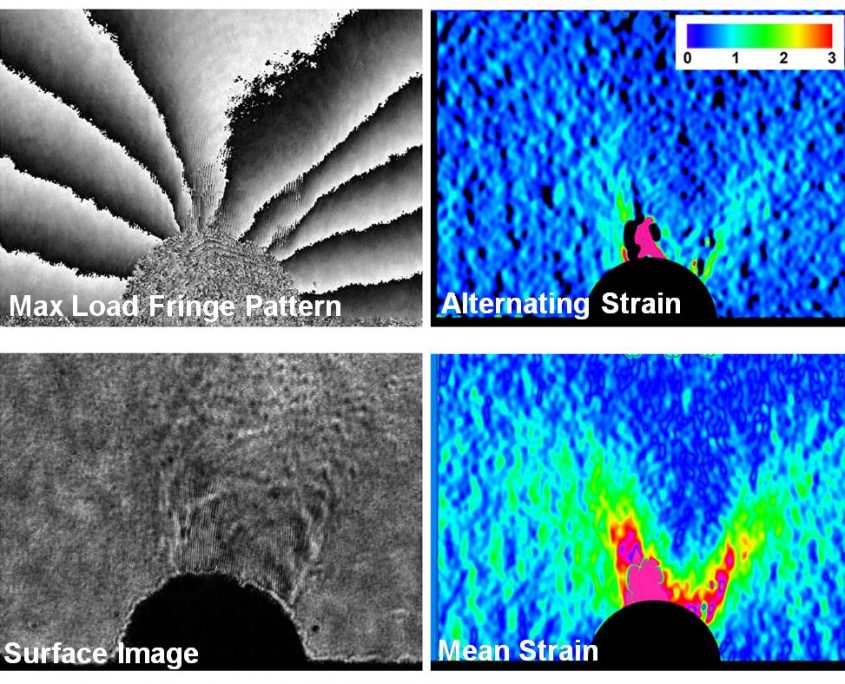

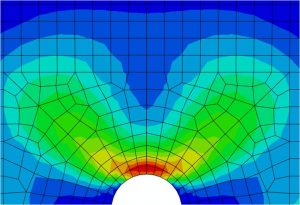

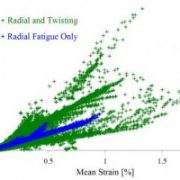

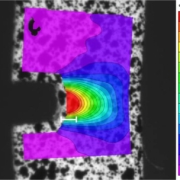

What follows are some of highlights of our presentation. The first image is a typical example of what we are interested in—a detailed analysis of a strain field in close proximity to a stress concentrator. In this case, a very simple semi-circular notch. Here the notch is subjected to a bending load and we are zoomed in really close. Shown (going clockwise) are a typical fringe pattern result at a maximum loading condition, alternating and mean strain contour plots derived from measurement data and finally an enhanced resolution surface image also obtained from measurement data.

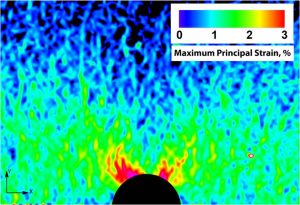

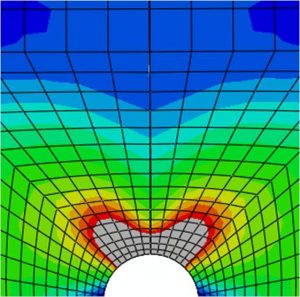

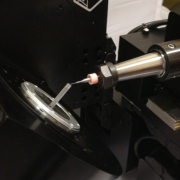

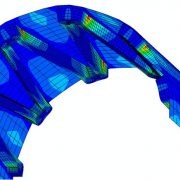

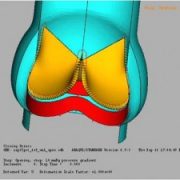

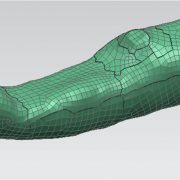

When you consider having this measurement capability and resolution, in situ, with what we have already described about our local strain measurement system, you can appreciate the extraordinary data available for evaluating different approaches to modeling the user material behavior of Nitinol. The next images is from our experiments and is followed by computational model results for two different ABAQUS user material subroutines for the same loading histories.

These are all plots of principal strain with identical contour levels (legend in first image) calibrated to the same material property data. Our technique reveals differences in real time where it matters the most—at the stress concentration. Neither model in this case accurately captures the localization and in general, all models have their advantages and disadvantages. We can help you select the right material model for a Nitinol application and robustly calibrate it so you can confidently make decisions to improve your product.

Contact us to learn about modeling Nitinol and the latest advances in medical device FEA.

Visit the ICCES website and learn more about ICCES 2016