Theory of Critical Distances and Design Validation

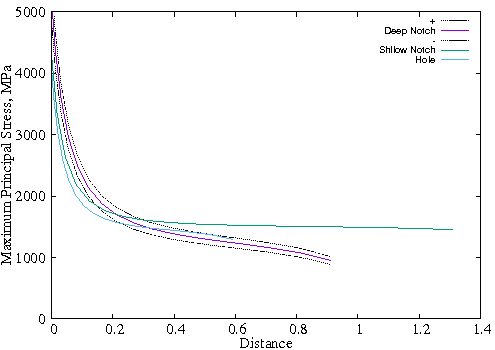

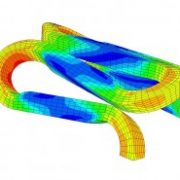

The Theory of Critical Distances (TCD) offers a powerful yet simple methodology for quantifying fatigue and fracture in real components. It involves making minor modifications to typical tensile specimens and testing them to fracture. Linear elastic finite element analysis is then performed on the modified geometries to obtain stress distance curves. Analysis of these curves provides both a critical distance and an associated limit stress value.

We generally find that the small amount of extra time it takes to modify the specimens more than pays off during product development and especially design validation. For example, we wanted to qualify different alloys and heat treatments for a new balloon expandable stent design. We used the TCD and were surprised to find a single critical distance for all of the samples. The additional insight offered through use of the TCD increased our confidence in setting the material and process specifications.

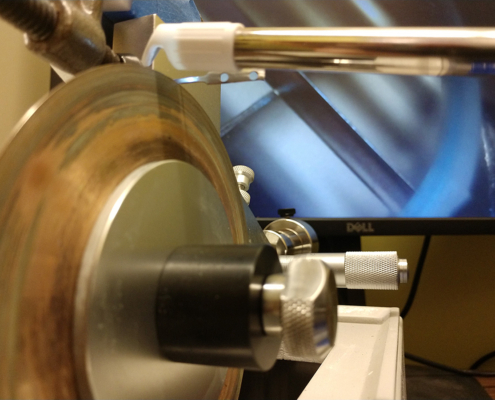

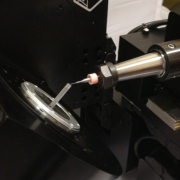

The modifications can be holes or notches. We like to use our Beuler IsoMet metallurgical saw, as shown below.

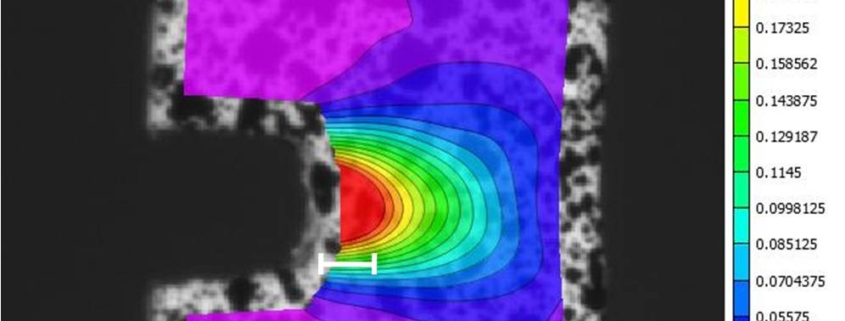

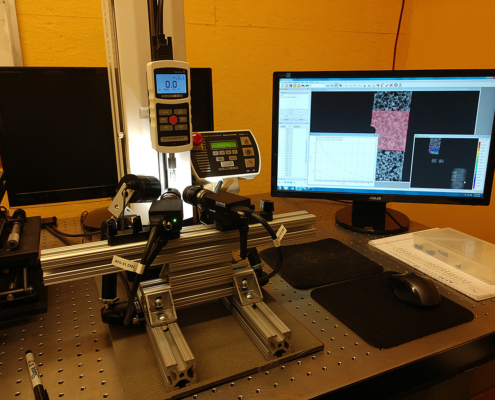

We also like to record DIC data at the same time since it is easy and facilitates data collection and analysis. Then we have measured strain distance curves which are useful for validating nonlinear materials models in FEA.

Please contact us for more information about design validation for medical devices.